- Equipment manufacturers must innovate continually to keep pace with technological advancements and meet customer demands effectively.

- Implementing strict quality control measures is crucial to ensure each product meets high standards of manufacturing.

- Efficient supply chain management and forming partnerships with reliable suppliers are essential to mitigate operational disruptions.

- Staying compliant with evolving regulations through robust processes and proactive communication with regulatory agencies is vital.

Equipment manufacturers play a crucial role in various industries, providing tools and machinery that are essential for production and operations. However, like any other business, equipment manufacturers face their own set of challenges that can impact their success. This blog will explore common challenges that equipment manufacturers face and discuss strategies for overcoming them.

Keeping up With Tech Advancements

One of the biggest challenges that equipment manufacturers face is staying ahead of technological advancements. With rapid changes in technology, manufacturers must constantly innovate and update their products to meet the demands of customers.

This can be a costly and time-consuming process, requiring investments in research and development. To overcome this challenge, manufacturers should invest in ongoing training for their employees and stay informed about industry trends to ensure they are offering cutting-edge products.

Quality Control Issues

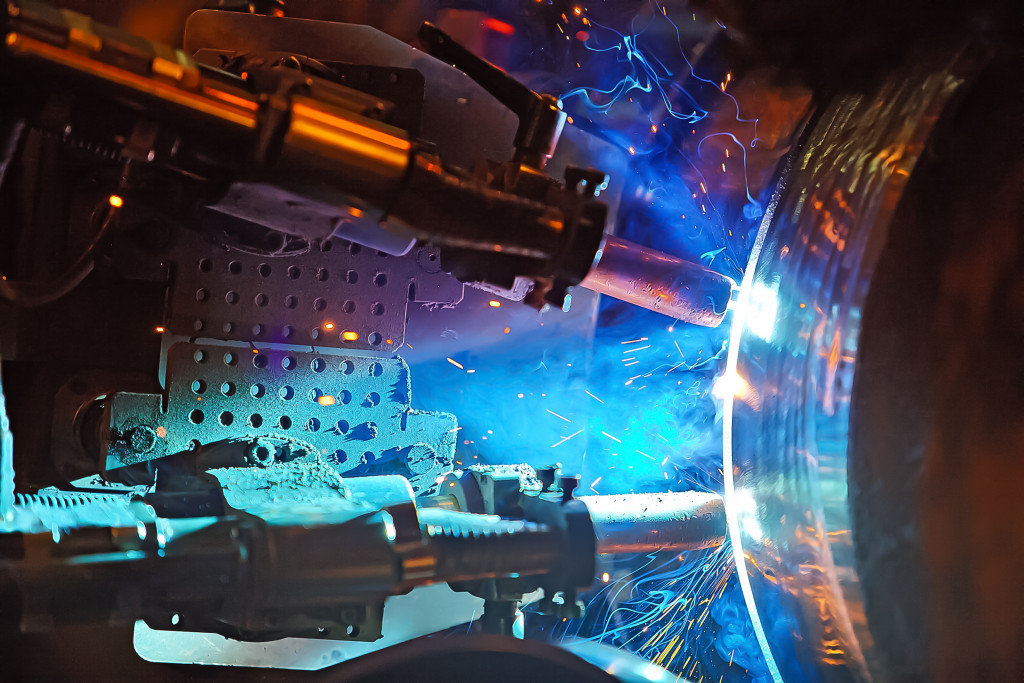

Another challenge that equipment manufacturers often encounter is maintaining quality control throughout the production process. Ensuring that each product meets high standards of quality can be difficult, especially when dealing with complex machinery and components.

Manufacturers can address this challenge by implementing strict quality control measures, conducting regular inspections, and investing in advanced testing equipment to identify defects early on. Additionally, involving employees in the quality control process and encouraging a culture of accountability can help maintain high-quality standards.

Supply Chain Management

In addition to technological advancements and quality control issues, equipment manufacturers also face challenges related to supply chain management. Managing a complex network of suppliers, distributors, and vendors can be challenging, especially when facing issues such as delays or disruptions in the supply chain.

To mitigate these challenges, manufacturers should create contingency plans for potential disruptions and use technology to improve visibility and efficiency within the supply chain. Partnering with reliable suppliers that have a track record of delivering quality materials on time can also help manufacturers maintain a smooth supply chain.

For example, a reputable metal supplier can provide high-quality materials for the production of metal equipment, reducing the risk of delays or defects in the final product. They can also provide valuable insights and recommendations for improving the manufacturing process.

Intense Competition

Furthermore, competition within the industry poses a significant challenge for equipment manufacturers. With so many companies vying for market share, manufacturers must find ways to differentiate themselves from competitors and attract customers. This could involve offering unique features or services, providing exceptional customer support, or developing strong branding strategies to build brand loyalty among customers.

Regulatory Compliance

Lastly, regulatory compliance is another challenge that equipment manufacturers must navigate. As regulations change and evolve over time, it can be challenging for manufacturers to stay compliant with various laws and standards governing their industry. To address this challenge effectively, here are four key steps manufacturers should take:

Stay Informed and Up-To-Date on Relevant Regulations and Standards

Staying informed on the latest regulations and standards related to the manufacturing of equipment is crucial for compliance. Manufacturers should regularly monitor industry updates, attend conferences and seminars, and consult with legal experts to understand any changes that may affect their operations.

Implement Robust Quality Control Processes

Complying with regulations often involves meeting specific quality control standards. Manufacturers should implement robust quality control processes to ensure that their equipment meets the necessary requirements. This could involve regular testing, documentation of processes and procedures, and tracking any changes or improvements made to the production process.

Maintain Accurate Record-Keeping

Accurate record-keeping is essential for compliance with regulations. Manufacturers should document all aspects of their operations, including raw materials used, production processes, testing results, and any changes or updates made to the equipment. This information can be used as evidence of compliance in an audit or investigation.

Communicate with Regulatory Agencies

Manufacturers should actively communicate with regulatory agencies to ensure they are meeting all necessary requirements and staying compliant. This could involve seeking guidance and clarification on regulations, reporting any incidents or non-compliance issues, and participating in audits or inspections.

By staying compliant and continuously monitoring and improving processes, manufacturers can ensure the safety and quality of their equipment while also reducing the risk of penalties or legal issues.

Equipment manufacturers are pivotal to industry success but face significant hurdles such as rapid technological changes, quality control, supply chain complexities, intense competition, and stringent regulatory demands. Overcoming these challenges requires continuous innovation, rigorous quality checks, efficient supply chain strategies, distinctive market positioning, and proactive regulatory compliance. By embracing these strategies, manufacturers can enhance their productivity and competitiveness in the evolving marketplace.