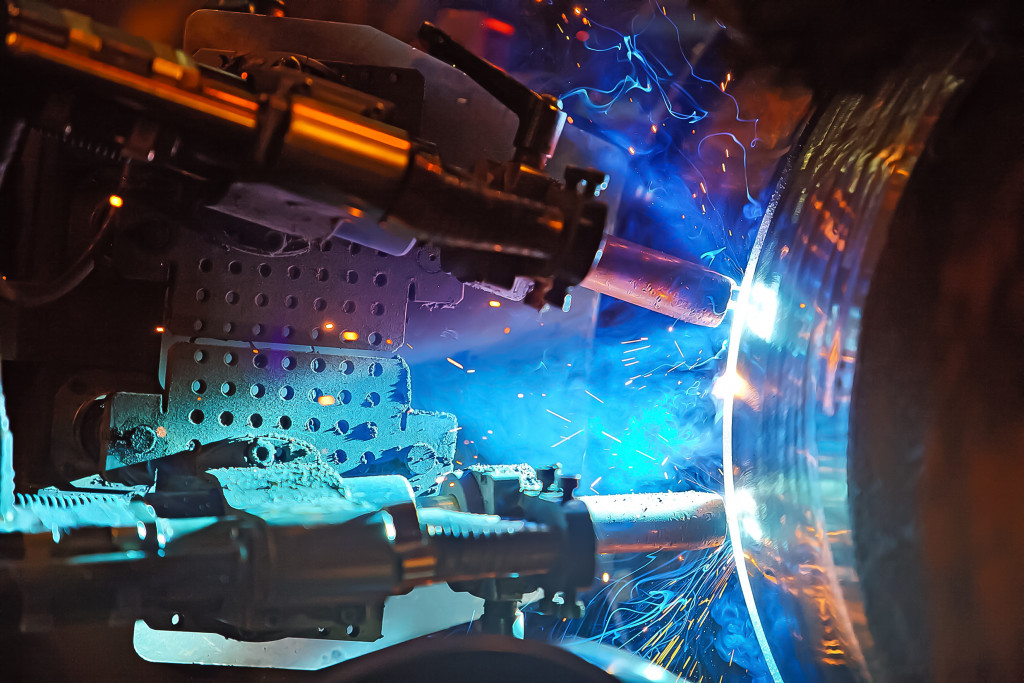

Manufacturing is an industry that often relies on automated processes and operations to maintain high efficiency and output. According to the National Institute of Standards and Technology (NIST), automation can help to improve quality, accuracy, and consistency in manufacturing operations. In addition, automated systems can often operate more quickly and effectively than humans, leading to reduced cycle times and improved throughput.

A study by the Manufacturing Institute found that manufacturers who implemented automated systems had a 6.2% increase in productivity and a 4.8% decrease in manufacturing defects. Furthermore, mechanical systems can help workplace safety, as they remove the need for workers to perform hazardous tasks manually.

Given the many benefits that automation can offer manufacturers, business leaders must consider implementing automated systems wherever possible. By doing so, businesses can streamline their operations, improve product quality and consistency, and create a safer workplace for their employees. However, maintaining it will be critical, starting with these steps.

Regular Maintenance Checks

Maintaining an automated operation is critical for businesses. One of the most important ways to do this is through regular maintenance checks. Companies can ensure they run smoothly and efficiently by routinely checking and servicing automated systems. In addition, routine maintenance can help identify and fix any potential problems before they cause significant issues.

Companies can do a few key things to pursue regular maintenance for their automated systems:

- They should create a schedule for regular checkups and repairs. You should tailor this schedule to the specific needs of the business and the computerized systems in use.

- Companies should ensure they have a qualified team of technicians who can perform these tasks.

- Companies should invest in quality maintenance and repair services to ensure that their automated systems are always in good condition.

Preventive Diagnostics

Preventive diagnostics helps to keep automated systems running smoothly by identifying potential problems before they occur. This type of maintenance can help businesses avoid downtime and reduce the need for repairs. Furthermore, it can also improve the overall efficiency of automated systems.

Preventive diagnostics involves using sensors and other monitoring devices to track the performance of automated systems. These sensors can identify vibration, excessive heat, or leaks. By detecting these problems early, businesses can take steps to fix them before they cause significant damage.

Control valve diagnostics will also be necessary for companies using automated systems. These valves regulate the flow of fluids and gases in manufacturing processes. If these valves are not working correctly, it can lead to disruptions in the manufacturing process. Therefore, it is essential for businesses to regularly test and calibrate their control valves to ensure they are working correctly. Fortunately, they can partner with a control valve profiler to help with this task.

Businesses should consider implementing preventive diagnostics for their automated systems. Doing so can help them avoid expensive repairs, improve system efficiency, and keep their operations running smoothly.

Operator Training

Another critical aspect of maintaining an automated operation is operator training. Operators must receive proper training to safely and effectively use computerized systems. Furthermore, they need to troubleshoot and fix any possible problems.

Operator training should cover various topics, including safety, system operation, and maintenance. By covering these topics, businesses can ensure that their operators are fully prepared to use automated systems. In addition, companies should provide ongoing training to keep operators up-to-date on new procedures and system changes.

Data Management

Data management is also essential for businesses using automated systems. This data can help companies track the performance of their systems. In addition, it can identify potential problems and find ways to improve system efficiency.

Businesses should set up a data management system that collects and stores information from automated systems. This data should be accessible to key personnel, such as managers and technicians. Furthermore, companies should regularly review this data to identify any potential issues. There will be a lot of data to sift through, so businesses may want to consider partnering with a data analyst.

By adequately managing data, businesses can improve the performance of their automated systems. In addition, they can avoid potential problems and keep their operations running smoothly.

Replacement Investments

Investing in replacement parts is another vital aspect of maintaining an automated operation. Over time, parts will wear out and need to get replaced. Therefore, businesses should have a stock of replacement parts on hand.

Having replacement parts on hand can help businesses avoid downtime. Furthermore, it can also reduce the need for repairs. Companies should only purchase replacement parts from reputable suppliers. In addition, they should keep track of the serial numbers of these parts to ensure they are getting the correct replacements.

Businesses should consider investing in replacement parts for their automated systems. Doing so can help them avoid downtime and keep their operations running smoothly.

Final Thoughts

By implementing these steps, businesses can maintain an automated operation effectively. However, it is essential to note that each company will have different needs. Businesses need to tailor their maintenance plans to their specific requirements. Maintaining an automated operation can help companies to improve their overall efficiency and quality when done correctly. Therefore, it is an essential task for all companies using such systems.